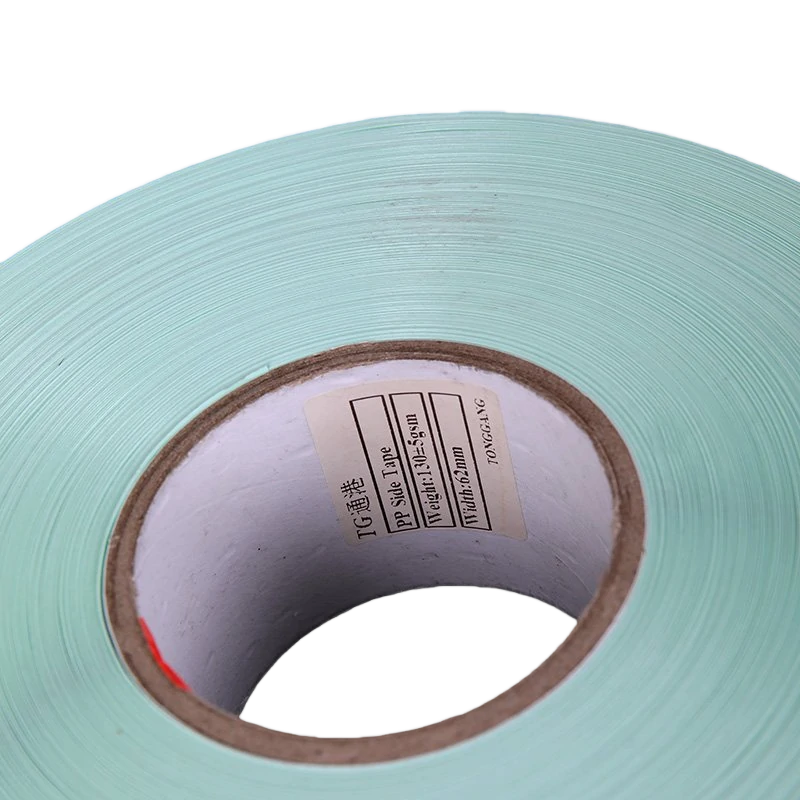

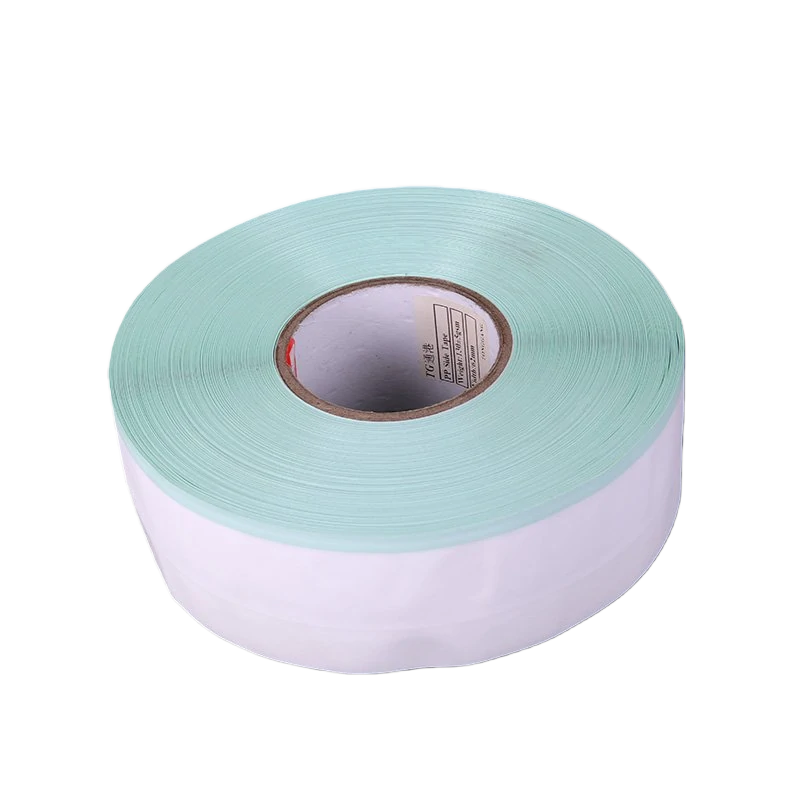

Magic Side Tape – Premium Fastening Solution for Modern Diaper Production

Product Overview: Reliable Fastening for Diapers

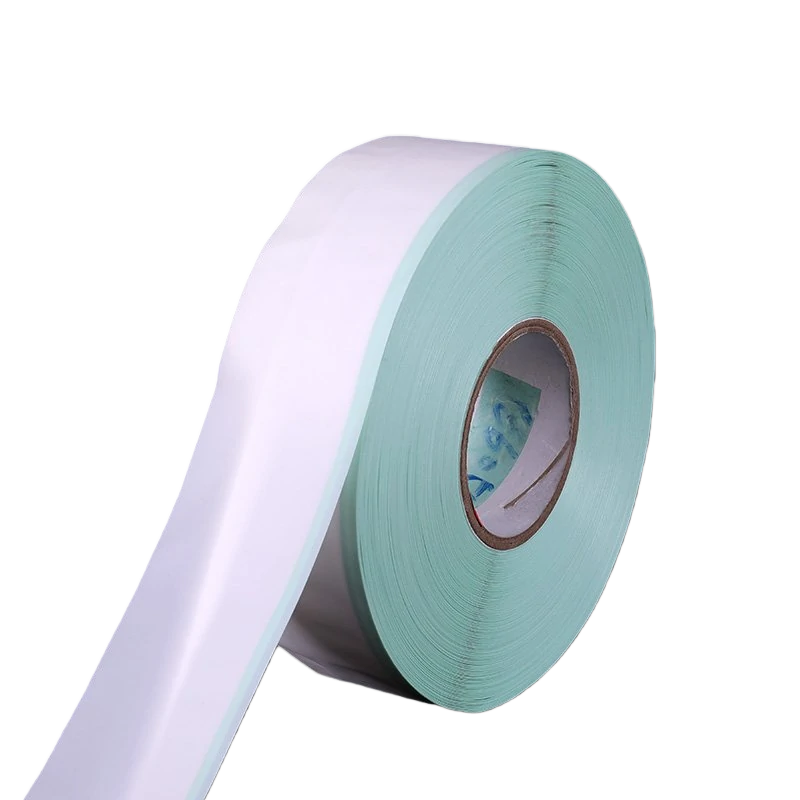

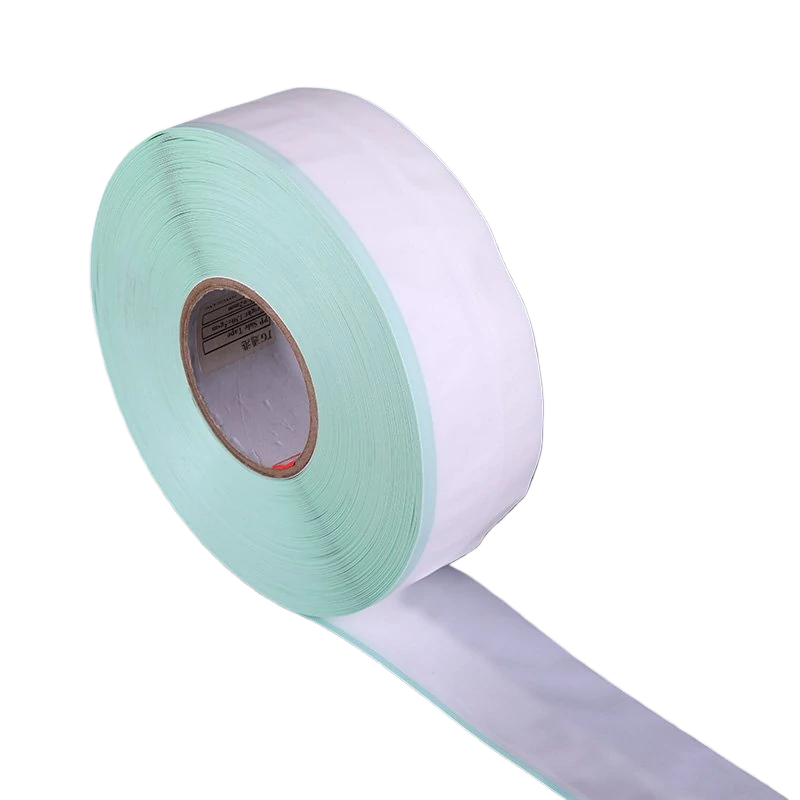

Magic Side Tape is a specialized waist-side fastening component for disposable diapers. We manufacture it using an advanced pre-composite pressure-sensitive adhesive process. This innovative tape integrates seamlessly with various diaper production lines while providing exceptional performance. As a result, it offers brand customers a reliable and comfortable fastening solution that ensures optimal diaper stability during wear.

Core Advantage 1: Superior Fastening Performance

The tape incorporates high-quality imported hook material that delivers exceptional holding power. Independent laboratory tests verify its static adhesion meets the highest industry standards. Specifically, it maintains a secure hold for 6-8 hours of continuous wear, effectively preventing detachment during infant movement. Additionally, its excellent tensile strength (≥8N/25mm longitudinally and ≥6N/25mm transversely) withstands vigorous pulling forces, completely eliminating breakage risks during daily activities.

Core Advantage 2: Enhanced Durability Features

This advanced side tape offers remarkable reusable adhesion properties. After multiple openings and closings, it retains over 70% of its initial stickiness while maintaining perfect shape without deformation. This crucial feature serves both end-users who need to adjust fit and production lines requiring precise re-positioning. Furthermore, the special wear-resistant coating provides superior protection against damage during warehouse stacking (up to 1.5m height), shipping, and high-speed production operations (≤300 pieces per minute), significantly reducing defect rates.

Core Advantage 3: Certified Skin Safety

We meticulously round and soften all edges for maximum safety. The skin-contact area maintains a surface roughness of ≤5μm through specialized processing. This thoughtful design effectively prevents irritation to infants’ delicate skin while fully complying with EU CE and US FDA contact safety standards. Moreover, the medical-grade pressure-sensitive adhesive contains absolutely no formaldehyde, fluorescent agents, or other harmful substances, demonstrating perfect 100% pass rates in all skin sensitization tests for premium brand requirements.

Core Advantage 4: Optimized Production Integration

The tape forms an exclusive adaptation system with Magic Frontal Film, creating perfect production harmony. Their consistent peel strength (maintained at 3-5N/25mm) ensures accurate bonding synchronization on fully automated production lines. This seamless compatibility reduces costly downtime caused by material adaptation issues by approximately 15-20%. We also provide comprehensive customization options by diaper size (S/M/L/XL), maintaining tight dimensional tolerances (≤±0.5mm) for perfect fit and higher manufacturing efficiency.

Sustainable Manufacturing Commitment

Our production process emphasizes environmental responsibility through reduced material waste and energy-efficient manufacturing. We continuously optimize our adhesive formulation to enhance performance while maintaining ecological standards. The tape’s reliable performance also contributes to sustainability by reducing diaper leaks and subsequent changes, ultimately decreasing overall consumption.

Why Choose Magic Side Tape?

-

Proven Reliability: Third-party verified performance metrics

-

Production Ready: Compatible with major diaper manufacturing systems

-

Skin-Safe Construction: Meets international safety standards

-

Customizable Solutions: Tailored to your specific requirements

-

Technical Support: Expert assistance throughout integration

Ready to Upgrade Your Diaper Fastening?

Contact us today to request complimentary samples and detailed technical specifications. Our specialists will help you integrate Magic Side Tape into your production process seamlessly.

double sided pp tape