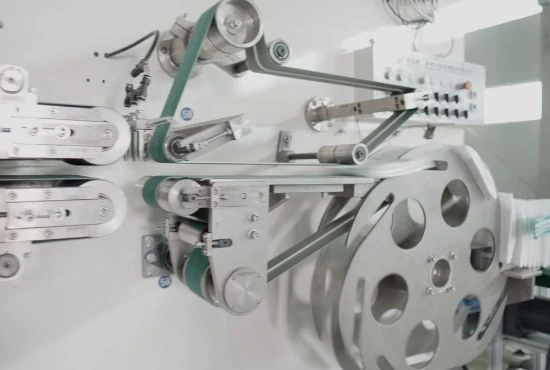

Advanced first-class production equipment

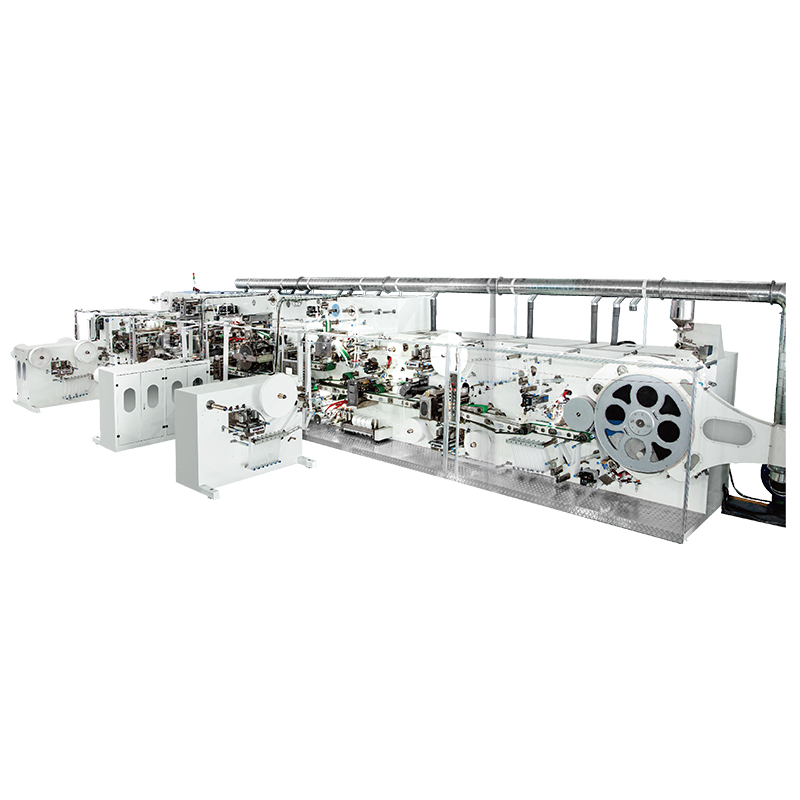

Full Servo Sanitary NapkinProduction Line

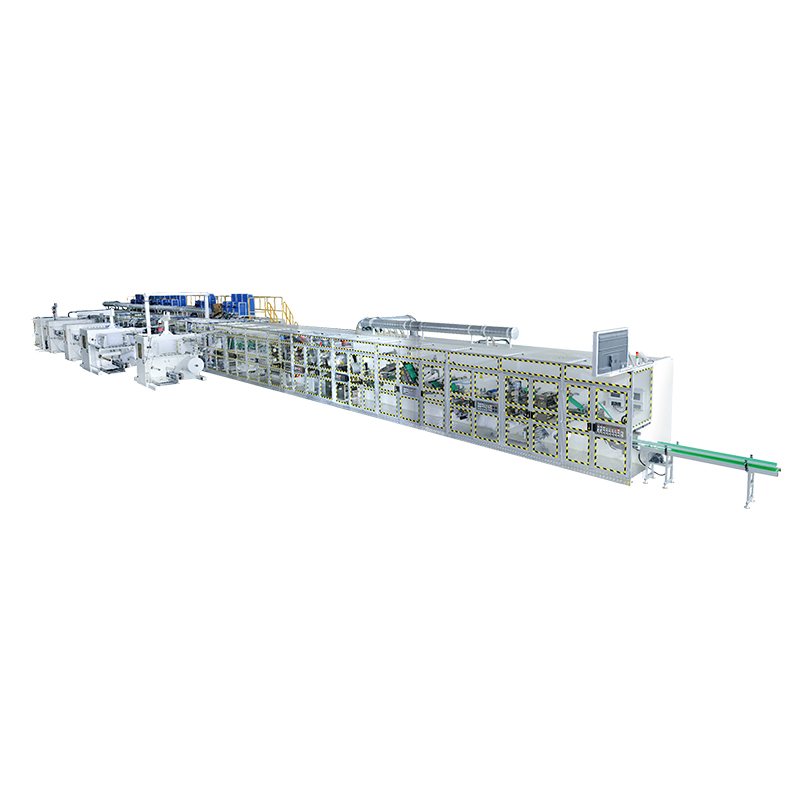

Pet Pad Production Line

Full servo adult diaper production line

Full servo I-shape baby diaper production line

Professional Sanitary Pad Machine Manufacturer in China

- We provide turnkey services: machine-materials-training

- Professional engineering team to customize machine plan based on client’s requirements

- Shorter manufacturing period without the influence of machine quality

- Convenient to solve PLC problems through remote services

- Complete coverage of disposable hygiene product equipment production

Why Choose Us?

Xiamen Rayhunt offers a complete range of hygiene product production lines and provides customized machine design services tailored to customers’ specific needs. Our product portfolio covers pull-up baby diaper machines, zero-waste elastic back-ear baby diaper machines, full-elastic waistband baby diaper machines, classic I-type baby diaper machines, pull-up incontinence pants machines, classic I-type adult diaper machines, sanitary napkin machines, panty liner machines, underpad machines, puppy pad machines, breast pad machines, and more.

raw material

- All Products

- Diaper Machine

- Diaper Raw Material

- Pad Machine

- Sanitary Napkin Raw Material

- See all categories

- Back

- TrainingPants Diaper Production Line

- Full Servo T Shape Baby Diaper Production Line

- Full Servo l Shape BabyDiaper Production Line

- Back

- Pet Pad Machine

- Sanitary Napkin ProductionLine

PROVIDES CLIENTS THE MOSTLY SUITABLE ONE-STOP SOLUTION OF DISPOSABLE HIGIENES MAKING MACHINES

Rayhunt Machine offers a comprehensive range of over 60 disposable hygiene product manufacturing machines, enabling flexible adaptation to diverse market demands and customized production needs of clients worldwide.

Leveraging a professional R&D team, Rayhunt Machine delivers one-stop personalized design services. We tailor technical solutions to match clients’ specific production scenarios and development goals.

In-house CNC workshop enables precise production of key components (plates, frames). Partnering with top international brands for spare parts ensures stable equipment performance.

Rayhunt Machine provides free on-site training during machine commissioning. Clients’ technical staff can receive hands-on guidance at our factory

To unlock the full potential of the equipment, Rayhunt Machine offers targeted support in recruiting seasoned operators for clients’ production lines, ensuring smooth and

Customized raw material recommendations and supply—matching equipment needs for consistent quality and efficiency.

WHO USE OUR DIAPER & SANITARY PAD MACHINES

Please Send Your Inquiries Now

FAQ

- Baby diaper equipment: Can produce 3-5 sizes;

- Sanitary napkin equipment: Can produce 1-2 sizes;

- Underpad equipment: Can produce 4-5 sizes.

- The equipment must be stopped when changing sizes;

- The specific time required depends on the operator's experience, and it usually takes several hours.

- We can provide raw material supply services according to the customer's actual needs and specific requirements;

- Relying on a mature supply chain system, we ensure the stability and compliance of raw material supply.

- The floor space occupied by the equipment is related to its production capacity; different production capacities result in slightly different space requirements;

- Under normal circumstances, the space required for the equipment is approximately 36m (Length) × 10m (Width) × 5m (Height) (L×W×H).

- Standard voltage: 380VAC, 50Hz;

- Customizable voltage: Supports 410VAC, 60Hz (adjusted according to the power standards of the customer's region).

- The power is related to the equipment's production capacity; different production capacities require different power;

- Regular installation power range: 250-600KW.

- High-speed full-frequency converter control equipment: One piece of equipment requires 1 experienced operator per shift;

- Full servo control equipment: One piece of equipment requires 1 experienced operator + 1-2 auxiliary operators per shift.